When a furnace is working one second and off the next a very common problem that could be occuring is the ignitor being bad. An ignitor is the ceramic composite part that will glow red and light the gases that flow through the gas valve and burner assembly. This ignition piece is very fragile and over time wears out and will need replacement. Replacement of an ignitor is one of the cheaper fixes that a furnace can go through and in some cases can be fixed by a well rounded handy person.

Lets first go through the steps a furnace should take when starting up:

- You turn the thermostat on and set the temperature desired.

- The circuit board in the furnace notices that the pressure switch is normally open.

- When that is determined by the board it then turns on the draft induction motor.

- When the motor turns on it pulls the pressure switch in and notices that the switch is closed to begin the cycle.

- At this point The board has a relay which gives 110v to the ignitor to light up.

- Afther the ignitor lights there is a delay and then the gas valve gets 24v to turn on.

- When the fuel/air mixture is lit the flame sensor notices flame and provides flame rectification through ground.

- There is a delay then the blower motor cycles on to circulate the air.

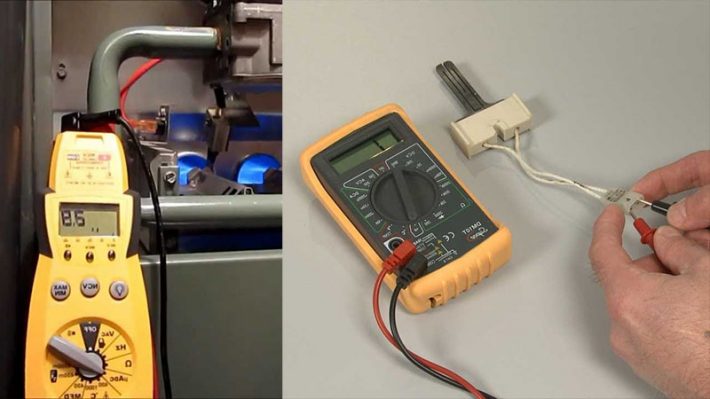

This is a pretty straight forward process on how a draft induced furnace should come on. If at the point where the ignitor should come on it does not there must be a problem. There is two ways to test this, and one works a bit easier so I will describe that one. Unplug the ignitor at the two pin connector, and put a volt meter on the leads that come from the furnace to the ignitor. Cycle the unit on again and wait fo the relay to click for the ignition cycle. If you have over 110v at the ignitor connector you can know that the ignitor is bad.