The washing machine was invented many years ago and has been improved many times since then. Unlike modern devices, the first units were not complex and could only perform a small amount of tasks. Now they are capable of a lot. This is very convenient for housewives, but becomes a huge problem if any malfunction occurs in the operation of a household appliance.

The most common problem with Kenmore 500 devices is reading stuck when they fail to function. If the appliance stops at the beginning of the cycle and cannot proceed to the wash, then the problem concerns one of three details.

The first reason is related to a malfunction of the water inlet valve or turning off its faucet. The second affects the gear shift drive and then it does not change its position before washing. The third concerns a failed control board.

Kenmore machines are renowned for their reliability and ease of use, which is why owners are so often frustrated when they fail.

The essence of the read cycle

These units are equipped with an automatic detection function, which serves to save water and control the washing process. This option ensures that only the required volume of liquid is used. Therefore, it is very useful for those who are not used to wasting it in vain.

The Kenmore home appliance is equipped with a Start button. When actuated, it starts the process of self-testing the lid lock. It starts after a click and a slight turn of the basket. Then it becomes clear that the panel is unlocked for a second, and then takes the position necessary for washing.

The Kenmore 500 then makes a series of slow and short rotations to determine the load size. Such a process serves to ensure that the mechanism of the aggregate evaluates the upcoming actions. After two or three minutes, its interior begins to fill with water. In the end, technology quickly turns a portion of things. Then he stops for a while so that the water soaks them.

From time to time, liquid is added to the Kenmore 500 until the washing machine determines the required volume. If it detects an insufficient or excess amount of water, then the sensor allows you to adjust its volume to start the process.

In other words, the Kenmore machine uses sensors to estimate the load on the clothes and how much liquid is needed to start washing.

An attentive hostess is able to notice that sometimes water does not completely cover things. There is nothing to worry about in such a shortfall, since the machine needs enough space to clean clothes. Do not add extra volume to the load, otherwise the laundry will float and not clean enough.

Reasons why the Kenmore 500 unit is stuck on reading

Sometimes it happens that the washers of a household appliance do not work when recognizing. This problem often occurs as a result of a breakdown of a number of parts.

Water inlet valve failure

This element is used when connecting hoses to the device and is responsible for regulating the fluid supply.

If the part fails, then the equipment cannot be filled with a sufficient volume of water or remains empty at all. The valve cannot be repaired, so if it is damaged, it must be replaced with a new one.

But first you need to establish the cause of the malfunction. A pair of inlet holes should be cleaned, which helps restore fluid flow. It also happens that the ports become clogged with limescale or debris. Then water also cannot fill the technique.

The valve also needs to be checked for various faults. It is quite easy to replace it, but repairs should be carried out using strictly defined parts and technologies. Such measures are specific to the specific Kenmore model.

- First you need to make sure that the electricity is completely turned off to power the equipment.

- Then shut off the water supply.

- After that, you need to take the pliers and unscrew the Kenmore supply hoses.

- You should make sure in advance that liquid does not leak out of them. Therefore, in order not to flood the neighbors, it is better to immediately put some container down.

- It is also necessary to check the filter screens of the washing machine

- On their grids inside the water supply valve, you need to look for a blockage, often causing damage to it.

- For such work, it is better to stock up on a flashlight and constantly monitor the screens of both ports. They cannot be replaced, so extreme care must be taken. Details should be thoroughly cleaned.

In the absence of blockages or calcium accumulations, it is necessary to check the condition of the solenoids of the water supply valve. Its continuity must be checked with a multimeter.

On different models, either the front or rear valve access panel must be removed. To determine its location, you first need to study the instructions.

The solenoid has two wires that need to be disconnected. Therefore, you need to immediately fix their position by sketching or shooting on the camera.

After that, to check the continuity of the circuit, set the multimeter to the “OHM X1” position. Place a probe across each terminal to check for resistance. If its readings are equal to zero or infinity, then the intake valve solenoid has burned out. Each of them must be checked separately. If at least one is broken, then you need to change the entire part.

Gear shift drive failure

Many top-loading Kenmore machines are equipped with a shifter. They are designed for the interaction of the transfer rings between washing and spinning.

At the beginning of the cycle, the control board monitors the condition of the tank and ensures that the drive is disconnected from the spin cycle.

It happens that for some reason it does not change the position to SENSING at the beginning of flushing or is not able to perform this function due to a mechanical or electrical failure. The control board will then continue to attempt to adjust the state of the shift actuator. After a series of efforts, the lid lock indicator will flash, indicating a malfunction. It can be argued that in this case it arose due to the drive.

To solve such a problem, you should go to the diagnostic mode and find the error code. It will be connected to the specified part and then you can be completely sure that it is broken.

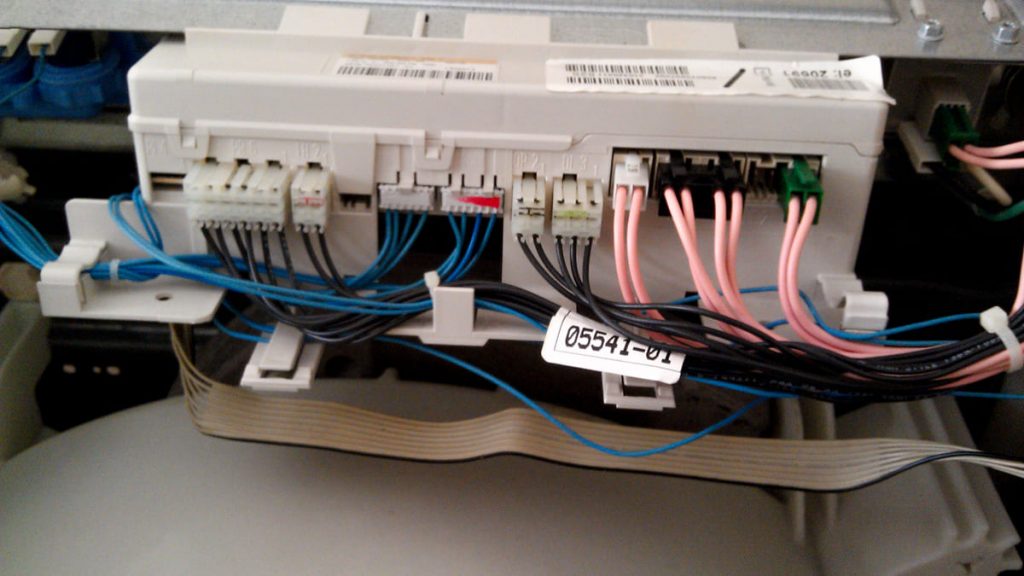

Damage to the main control board

There is also another, not too common, but significant reason. It is connected to the main control board.

This part stops responding to signals coming to it due to a wiring or electrical circuit failure. This also happens due to corrupted software, which is already a serious difficulty.

Then you need to check all the connectors of the motor, gear selector and control board. It is also worth making sure that they are all securely fastened. If there are no problems with these parts, then you will have to change the main control board.