Many owners of Whirlpool dishwashers, as well as other brands, may find themselves in an unpleasant situation. It happens that the equipment, after loading dirty dishes into it, starts to draw water for washing, but does not start the cycle. This problem forces users to take the dishes back out and wash them by hand. In any case, the problem must be corrected.

There are two common problems that cause a dishwasher to stop cleaning. The first of them is associated with a breakdown of the circulation pump. The second malfunction is related to the clogging of the sprinkler holes. Let’s consider for what reasons the Whirlpool PMM can stop performing the specified functions.

Malfunction of the circulation pump or washer motor

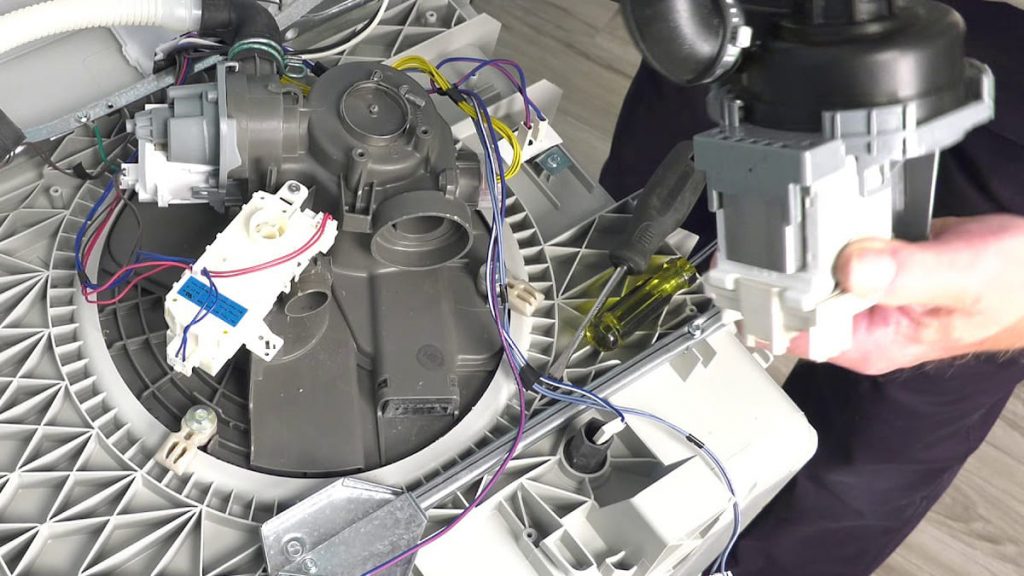

Breakdowns in the circulation pump or washer motor prevent the dishwasher from starting the washing cycle, while water flows freely through the hose. To check the performance of the system, you need to find the engine and listen to the sounds it makes. Loud clicks indicate engine failure. In addition, if a couple of minutes after starting the PMM does not start washing, a motor breakdown is confirmed by 99%.

- Turn off the power to the device, and also disconnect it from the water supply and sewerage.

- Find the engine by first laying the machine on the floor.

- The motor is behind a protective panel and plate, which should also be removed.

- Disconnect the wires from the harness attached to the motor.

- Using a multimeter, check the resistance by setting the desired value.

- Also, check for grounding by placing a probe on the exposed motor housing and another on the terminal.

If during the check it turned out that the values do not correspond to normal indicators, then the engine is broken and needs to be replaced.

To replace the motor in a Whirlpool dishwasher, you should focus on the following algorithm of action:

- Turn off the power and water supply. It is important to make sure that when you press the control buttons, the panel does not light up.

- Open the PMM door and pull out the lower basket. By releasing the stops on top, the owner will be able to pull out the top tray.

- Remove the lower front panel and striker plate by loosening the screws with a wrench.

- Together with the dish trays, it is important to remove the lower spray arm and filter. Place a towel over the water supply area in case of a sudden leak or to prevent electric shock.

- To gain access to the engine, you will need to put the machine “on its back”. Next, you need to disconnect the wiring harness and remove the screws and the motor.

- Install the new motor in the tank, and secure the latch. It is important to remember to connect the wire harnesses and install the screws in place.

- Restart the dishwasher by first sliding it into its niche and connecting the hose to the drain.

- Restore the water supply and power by connecting the PMM to the outlet.

If a leak occurs during start-up, its origin must be determined. If there are no leaks, you can start the wash cycle. The machine should not only draw water but also wash the dishes. If the problem is not solved, then the malfunction is hidden in another.

The nozzle holes are clogged: what to do?

If your Whirlpool dishwasher isn’t washing dishes, or it doesn’t do it well, then the problem may lie in clogged spray holes. On the one hand, the owner can clean them himself using thin metal wires. Unfortunately, the holes get clogged over time in most PMM models. Clogging is provoked by food particles, hard water, and mineral deposits.

For more thorough cleaning, you should resort to another method. To do this, you will need to disassemble the rocker arms with nozzles. First, you need to turn off the power of the machine and turn off the water supply.

The algorithm of work after that looks like this:

- Open the door and pull out the bottom dish tray.

- Rotate the spray arm from below 60 degrees and remove it.

- Remove the top dish tray.

- Rotate the top atomizer by pushing it up.

- Clean the nozzles with a toothpick or fine wire.

- Inspect the rubber seals for deformation.

- We assemble the elements and launch the PMM.

If the holes are very clogged, then you can soak the rocker in warm water with vinegar. The solution will remove most of the deposits. Having fixed the sprinkler, the owner must make sure that the fastening is secure. Different models have different fasteners, so you should read the instructions before assembling, otherwise, there is a risk of breaking the latches. When all the details are in place, you can start testing.

Tips for the operation and repair of PMM

To prevent problems with the performance of the PMM, it is important to regularly carry out a preventive fight against scale and unpleasant odors. As a rule, not only food leftovers, but also the mold is a source of musty “aroma”. In cleaning parts, you do not need to use household chemicals with acid and alkali in the composition. Aggressive components act on parts in a destructive way.

As for the care of the water circulation system, you need to know that deposits form on the walls of the pumps during operation. The throughput of the system decreases, and the pressure rises, which negatively affects the operation of the circulation pump. In order to prevent this, you should regularly clean the PMM with special tools. They are available as gels or liquids. In combination with hot water, the mixture will be able to remove deposits, which will prevent pump failure or rupture of system tubes.

If a breakdown does occur, it is important not to take any action without first diagnosing it. During repairs, you should follow the instructions and not try to act at random. Rash actions or lack of skills are a reason to turn to specialists.