Most modern Whirlpool washing machines are equipped with a touch function. When the next laundry cleaning cycle starts, it starts with the determination of the internal load. At this time, the unit automatically selects the appropriate water level depending on the amount of laundry placed in it.

Whirlpool appliances usually stop during the measurement phase for only 2-3 minutes. If they get stuck in this position, then most likely the following things have happened:

- malfunction of the gear change drive;

- failure of the water inlet valve;

- a problem with the main control board;

- malfunction of the drive motor.

Changing the normal functioning of each of the listed parts may prevent the washing machine from going beyond the measuring stage. For those who are poorly versed in its design, diagnosis may not be too simple. Therefore, first you need to read the guide, which will:

- The features of the indicated parts are described.

- Explanations of their functionality are given.

- A story about their breakdowns is presented.

- Advice is given on how to solve such problems.

There are a number of reasons why machines cannot progress past the reading stage. This section will explain each of them, as well as explain how to fix its breakdown.

Difficulties with the water inlet valve

Such a valve in the Whirlpool unit is responsible for controlling the supply of clean water. It is a mechanical part with moving parts controlled by electricity.

When a new wash cycle begins, it opens and allows the water to move freely into the drum. After filling it, the machine sends a signal to the water inlet valve. Then its flow will be blocked and stopped. Such actions prevent the unit from overflowing and prevent floor flooding.

However, there is a possibility that the process is taking too long. Therefore, it seems that the appliance is stuck in the Sensing stage and therefore does not start the wash. An excessively slow flow of water is usually caused by a malfunction of the electricity leading to the supply valve. This mechanical part is also sometimes contaminated or corroded near the valve, preventing full function. Such problems in many ways slow down the process.

In addition, a failure in the operation of electricity can lead to the fact that the water supply part does not receive the necessary amount of energy for its functioning.

The intake valve cannot be repaired. Therefore, in the event of a mechanical or electrical nature of its breakdown, it will be necessary to replace the element with a new one.

It is very important to gain access to the inside of the device from behind. First you need to remove the screws holding it in place. Then disconnect the wiring and connected hoses. After that, you need to install a new part in its original place and connect the equipment accordingly.

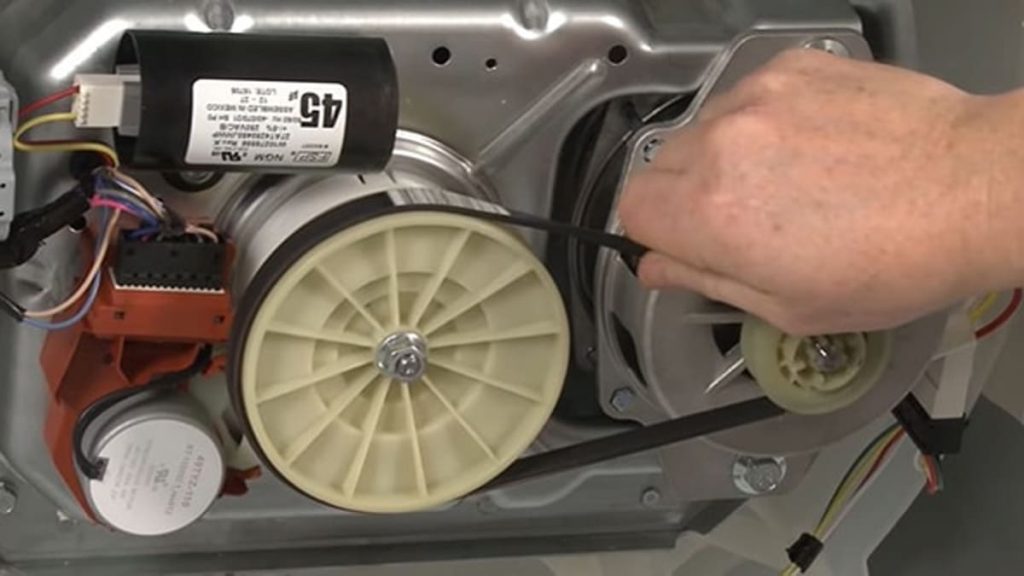

Shift Drive Malfunction

The gearshift drive is responsible for a number of functions that allow Whirlpool to move to the next stage of washing.

- If necessary, inside the washing machine, the actuator mechanically moves the cam ring.

- At the same time, he controls the cry, which must always be in the correct position.

- In addition, the shift actuator is equipped with an optical sensor that monitors the position and transmission speed of the Whirlpool machine.

- If it gets stuck on the sensor, then you need to make sure that the gearshift drive is working. If it is broken, then the unit will not proceed to the next stage of washing.

This part usually breaks as a result of a mechanical or electrical failure. The first option occurs due to a common material defect. Power problems lead to the fact that the element is damaged due to a short circuit or power surge. And water leakage through the tank seal can cause damage to the switch or drive.

If a part fails for the reasons listed, it should be replaced. But first it needs to be carefully examined and checked with a multimeter. If a defect or damage is found due to the fault of electricity, the element should be replaced with a new one.

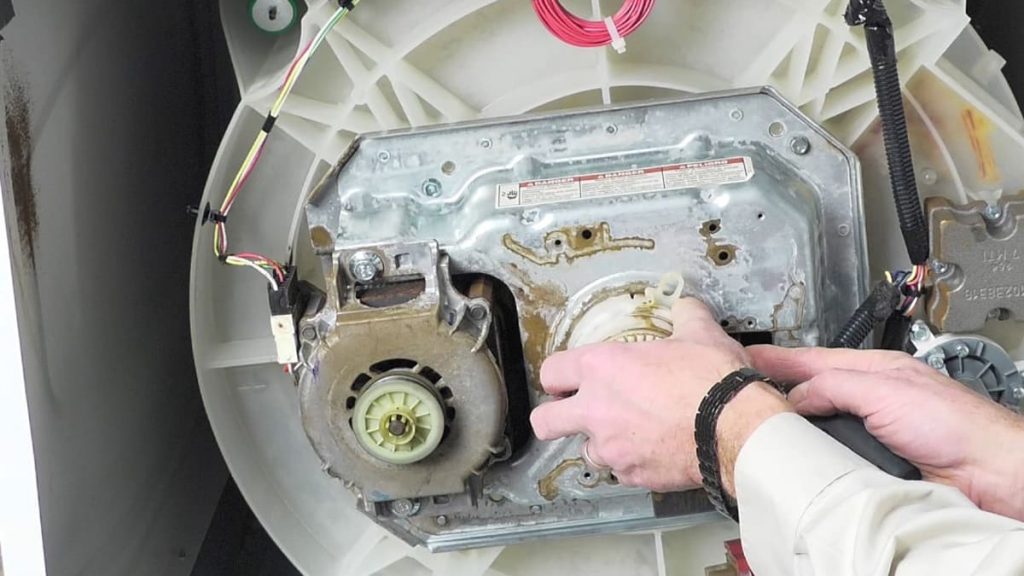

Engine problems

The drive motor is the heart of the Whirlpool washing machine. It is powered by electricity, after which it generates energy that rotates the drum in both directions. While the unit is in the measurement stage, the part rotates the drum from time to time. Such actions allow the household appliance to check the internal load and select the wash cycle accordingly.

It is not uncommon for a Whirlpool machine not to move out of the measuring phase as a result of a problem with the drive motor, which often suffers from electrical damage and general wear and tear. A defective part can prevent the unit from completing the current stage and proceeding to successive washing stages.

This element of the Whirlpool machine is sometimes also damaged by electric current, like all other parts of it. A short circuit or a power surge can damage any part of the motor, disrupting the normal operation of the unit.

It is also necessary to take into account the period of his service. The longer it is, the greater the threat that the engine is worn out becomes. Especially often these situations happen with regular overload of clothes. The drive motor is also beyond repair, which means it will have to be replaced. It is very expensive, so it must be handled with care.

Before buying a new one, you need to carefully inspect it. Typically, household appliances and their main parts function for about 10 years. Therefore, if their age is much higher, you should think about purchasing new equipment.

Breakdown of the main control panel

If the drive motor is considered the heart of the Whirlpool, then the main control circuit board becomes the brain of the washing machine. It has a huge number of small elements, each of which is responsible for certain functions.

If the troubleshooting is complete and the damaged part is still not found, then you need to pay attention to the main board. Typically, a problem with it affects a number of machine functions. Therefore, if it is enabled and fully functional, a broken part can cause it to get stuck at the recognition stage.

Technically, only the main parts of the main control board can be repaired. There are few of them, so do not fight them. When establishing the fact of damage to the control element, it is better to purchase a new one.

FAQ

There are several questions and answers that should be touched upon to help fix Whirlpool appliances stuck on the sensor.

What is resetting the settings?

The easiest way to reset the washing machine is by turning it on and off. First you need to remove the plug from the socket. Then it is worth leaving the unit for 5 minutes, and then reconnect it.

Why do you need a factory reset?

Resetting the home appliance helps to eliminate the electronic failures that have occurred in it. These include power outages or power surges that may cause the WhirlpoolCabrio to malfunction. Resetting its settings allows you to restore normal operation.

How long should a Whirlpool washing machine be left on?

The reading step typically lasts 2 to 3 minutes. But in a number of situations, the unit needs more time, so it should be provided to it in order to troubleshoot problems that arise.

Why is a sensor required?

Some models of such household appliances start the wash cycle already at the detection stage in order to allow the device to control the internal load. This part of the process usually ends in 2-3 minutes.

How is the water level determined?

Whirlpool technology detects the internal volume of a liquid by means of a pressure switch. This mechanical switch inside the washing machine is connected to the air tube.

When the water filling the tank reaches a certain level, the air is activated, signaling the switch.