Nowadays, there are different types of vacuum cleaners that efficiently and quickly clean the room from dust and debris. Some models easily cope even with wet cleaning or, for example, with air filtration. There are devices that are equipped with the function of ozonation, or air ionization. All of these cleaning aids need basic cleaning and maintenance to last as long as possible. It is hard to imagine how to keep the apartment clean without this handy assistant.

Shark brand vacuum cleaners are high-quality devices with excellent suction power. But, like any technology, over time, they have malfunctions. For example, models with vacuum suction become less efficient. This problem is usually caused by a full garbage bag. In addition, the air movement can be blocked due to debris and dust stuck in the hose. In this case, you need to check the operation of the motor, as well as the internal system of the vacuum cleaner.

Consider what problems owners of Shark devices most often face.

Overflowing garbage bag

Remember the last time you emptied the dust container or changed the bag inside the vacuum cleaner? Many people forget about regular cleaning of the system from accumulated garbage. As a result, an overfilled tank or bag reduces the suction quality because it is completely filled with dirt.

Every time you turn on the vacuum cleaner, it starts to suck up dust, but does it weakly. To fix the problem, you need to clean the system of accumulated dirt. Only in this way will you restore smooth airflow and return suction power to its original level.

The paper dust bag is usually replaced with a new one. The fabric bag can be shaken out, washed, dried and re-inserted into the vacuum cleaner.

Blockages

A vacuum cleaner is a device in which not only the dust collector is clogged, but also the hose, tubes or brush. If everything is in order with the bag, then it is worth checking these elements for clogging. The hose, for example, may not be fully inserted into the body, which means that the suction power will not be enough for high-quality cleaning. In the telescopic tube, in turn, small debris, threads, napkins, candy wrappers and buttons often get stuck. You can check the degree of cleanliness of the tube using a metal wire or a coin. We wipe the vacuum cleaner body with a damp cloth to avoid accumulation of dust.

A blockage in the tube is accompanied by the following symptoms:

- The vacuum cleaner makes a lot of noise and howls;

- There is a smell of burning;

- The garbage is practically not sucked up.

In addition to a clogged tube, you may run into problems with stuck motor bearings or improper brush installation. To eliminate these troubles, engine oil is required. Bearings should be lubricated with oil, and the brush should be set in the correct position.

It is important to inspect the hose not only for blockages, but also for defects. Cracks in the surface create air leakage. For this reason, debris cannot be drawn in. Such a hose is recommended to be changed completely.

To clean a conventional vacuum cleaner, the hose, tubes are always removed and all this is washed under running water. It is advisable to do this procedure regularly, at least once a month. Don’t forget to empty the dust bag or empty the bin as often as possible.

Fine filters

Vacuum cleaner filters also need regular cleaning. Many users of Shark vacuum cleaners, unfortunately, pay more attention to dirty dust collectors than fine filters. During operation, they are filled with dust. One filter element is installed in front of the fan. For cleaning, you need to remove the part and rinse it in water. Behind is a plastic case, which is also thoroughly washed.

The second filter element is located on the exhaust. It prevents the remnants of the collected dust from re-emerging into the air. The part is also cleaned using a brush and then washed with water. Over time, the filter must be replaced with a new one.

It is important to understand that worn and old filters reduce the traction of the vacuum cleaner. If 70% of the space is filled with debris, then the suction process may disappear altogether. In order to prevent such situations, we recommend cleaning the filter elements once a week, and not after the appearance of problems. If after cleaning the problem has not disappeared, then proceed to the next step.

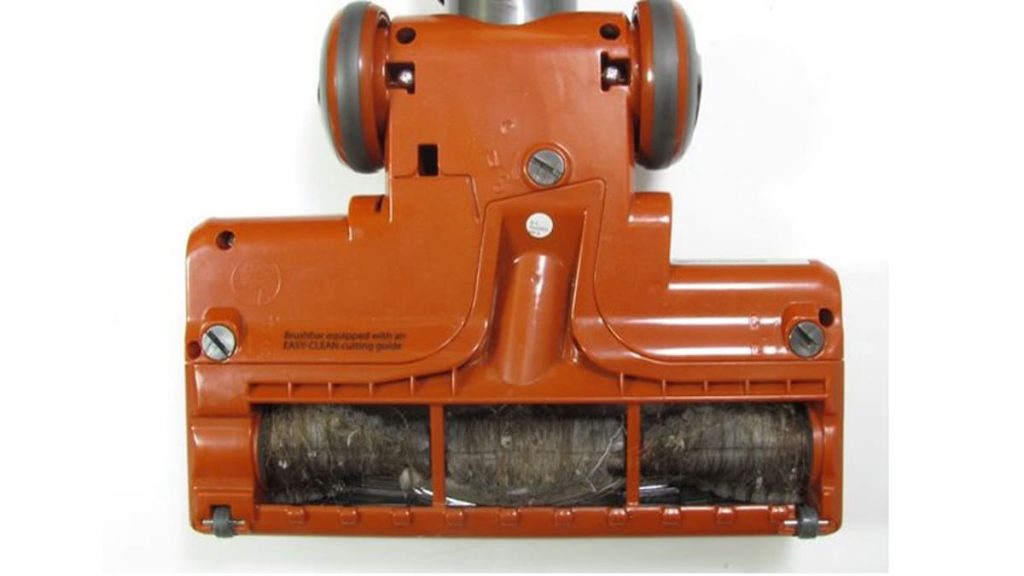

The brush has stopped turning

Many models of Shark brand vacuum cleaners have a brush rod, which is also called a “brush roller”. This brush has a simple purpose: it rotates, at the same time it collects dirt, making it easier to suck dust from the floor. Often hair, threads and other debris are wound around the brush. It stops rotating, and the suction power of the device decreases.

To deal with the problem, you need to disconnect the brush from the vacuum cleaner. Next, you need to carefully examine it. If the rod does not rotate, then too much dirt, hair or animal hair is stuck to it. Tangled debris can be removed with scissors or a blade. It is important not to damage the bristles of the brush. When the part is cleaned, it will start to rotate again as before. The normal suction of the vacuum cleaner will be restored.

Suction leak

In order for a Shark brand vacuum cleaner to clean properly, it is necessary to provide maximum suction. A leak usually occurs when a corrugated hose breaks “on edge”. This damage is difficult to notice immediately. Air escapes through the resulting hole, reducing the suction power.

To deal with the problem, we advise you to inspect the hose. If there is indeed damage, you will have to replace it. Do not wrap the hole with tape. The leak will still persist. The only correct option is to completely replace the hose.

The vacuum cleaner has overheated

Overheating of the vacuum cleaner is a secondary problem that occurs against the background of the previous ones. A dust collector filled with garbage, problems in the operation of the engine or failed components – all this provokes the heating of the case, and then the incorrect operation of the equipment.

If the case heats up, it is worth identifying the cause, based on the following algorithm:

- First of all, you need to disconnect the hose and turn on the device again. If the case does not heat up, then the problem was hiding in the hose or in the telescopic tube.

- After that, we advise you to check the inlet of the device. Perhaps there is a foreign object that interferes with the normal operation of the vacuum cleaner.

- Next, remove the dust collector from the system and start the vacuum cleaner again. If heating still occurs, then proceed to the next step.

- Overheating is often caused by dirty filters. If you haven’t cleaned them yet, now is the time to do so.

If you checked the performance of the vacuum cleaner in all respects, but it still continues to heat up, then the malfunction is hidden in the engine.

It is often not possible to repair the engine yourself. Without special knowledge, it is difficult to determine the exact cause of the breakdown. This could be a fuse, a broken winding within the system, or an open contact.

Engine problems

Engine problems are rare. They usually occur after prolonged use of the vacuum cleaner. At first, the user hears a strange noise and hum. This indicates that the bearings have dried grease. If the vacuum cleaner turns off after turning it on, it means that the overheating system has worked. How to fix this problem is indicated in the previous paragraph.

If the device has stopped sucking, and you are sure that the problem lies precisely in the motor, then you should take one of the following solutions. First of all, you need to check the mains voltage. In rare cases, this is how it affects the operation of the device. The problem of low voltage in the house is solved by installing a step-up transformer.

If everything is in order with the flow of electricity, then try to inspect the engine. To do this, remove the back cover and conduct a visual inspection for mechanical damage. In most cases, you will not be able to fix the problem yourself. You will need to replace the engine with specialists, or purchase a new device, since often the master does not undertake to repair old equipment.