When a washing machine fails, error codes come out that indicate what exactly went wrong in the process. Error codes do not show which particular part needs to be replaced, they signal in which area there is an obstacle to smooth operation.

List of codes

Suds (5D, SD)

The Sud error occurs when there is too much foam in the drum. It prevents rotational movements at the speed at which it is necessary in accordance with the washing phase. When an error occurs, the device tries to clean the drum with water, this may take some time.

If the washing machine did not cope with the task on its own, you need to check the drain pump filter and drain hose and clean them if necessary.

F0E1 (Rl)

An error that occurs while cleaning the washing machine. It means load detection inside the drum. Usually, restarting the washing machine is enough to solve the problem.

F1E1

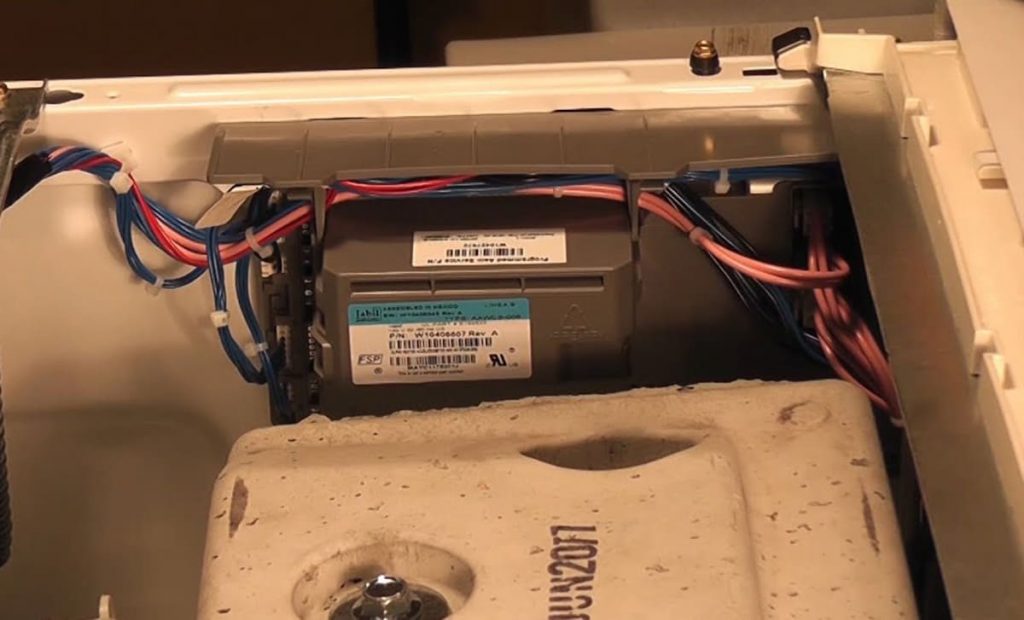

Error in the central control unit. As a rule, this concerns either an error in the firmware of the washing machine, where service data about the device is stored, or the control unit itself. It is also possible to break the connection between these two elements.

To eliminate, check the serviceability of the outlet with which the washing machine is connected to the network. If there is no damage on it, then there may have been a voltage drop, which led to the appearance of the code. In such a case, disconnect the device from the mains electricity, and then reconnect it. If the error code does not disappear, check if there are any accidents with electricity in the house.

F1E2

Error code F1E2 is associated with the engine control unit. Moreover, the problem makes itself felt when there are problems in the network: power surges, overloads of the electricity network, and so on.

Also, the problem occurs during a quick spin, this is due to the loss of a signal to the engine control unit. Restart your device to resolve the issue.

F2E3

Error F2E3 means that the wash phase, which is signaled to the command center via the interface, is not available on this particular device.

F3E1

The central control unit signals the occurrence of unacceptable pressure. The problem is related to the pressure sensor. First of all, check the connection chain: drum – pressure switch tube (air trap) – pressure hose – pressure sensor. Eliminating the detected error on one of the sites will eliminate F3E1.

F3E2

The temperature sensor responds to abnormal water temperatures. As a rule, the problem lies in the sensor itself, and not the water temperature.

F4E0

The central control unit does not detect the heating of the water in the drum. This most likely means that the heating element is not working: it can either be disconnected or be broken.

F5E1

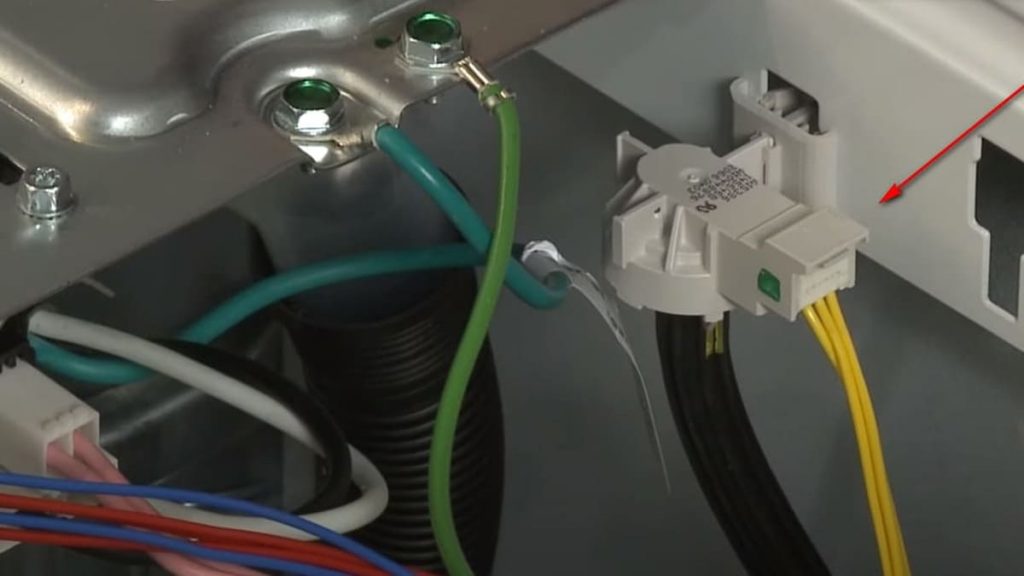

The door switch does not work. In other words, the automatic door lock/unlock process is broken.

F2E2

Washing machine door does not close properly. Perhaps the door lock has become inoperative, a foreign object is preventing the door from closing completely.

F5E3

During washing, the mechanism of the washing machine automatically opens and closes the door to check the operation of the lock. If the mechanism fails to unlock the door 6 times, it displays an error code. Do not try to open/close the door by force, it is better to check that the lock is firmly attached to the body and that the door latch is not damaged.

F6E1

Communication between the central control and engine control units is broken or not detected. To solve the problem, check the connecting wires of the elements, the door switch, the drive system.

F6E2

Disruption of communication between the central control unit and the display of the washing machine.

F6E3

Communication between the central control unit and the display of the washing machine was not found. Most likely, the failure occurred due to a break in the connecting wires. But it is also possible that the problem is caused by current and voltage surges in the electricity network.

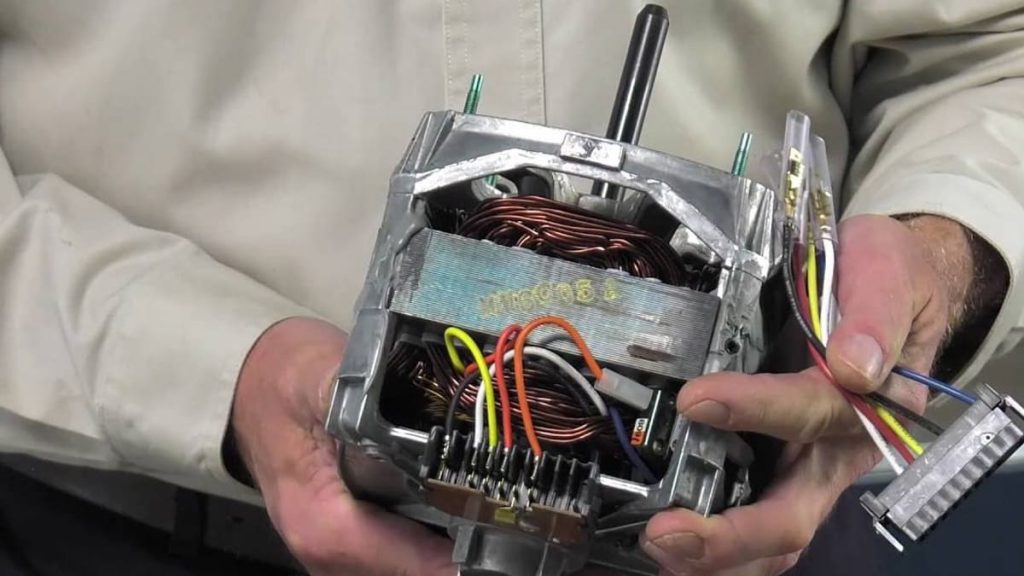

F7E1

The error is related to the engine control unit. The fact is that he cannot recognize at what speed the engines are running. Usually the error appears in the active mode of the device.

To solve the problem, you can try restarting your device. It is also necessary to check the drum of the device: it should rotate smoothly.

F7E2

The central control unit signals overheating in the engine control unit. As a rule, the problem goes away by itself after the washing machine engine cools down. However, in case the problem persists, check that the washer is installed correctly, the drive system and the drum rotates smoothly. Also, the appearance of the F7E2 error code may be affected by: the presence of additional heat sources near the device, lack of ventilation, an excessive amount of clothes loaded into the drum.

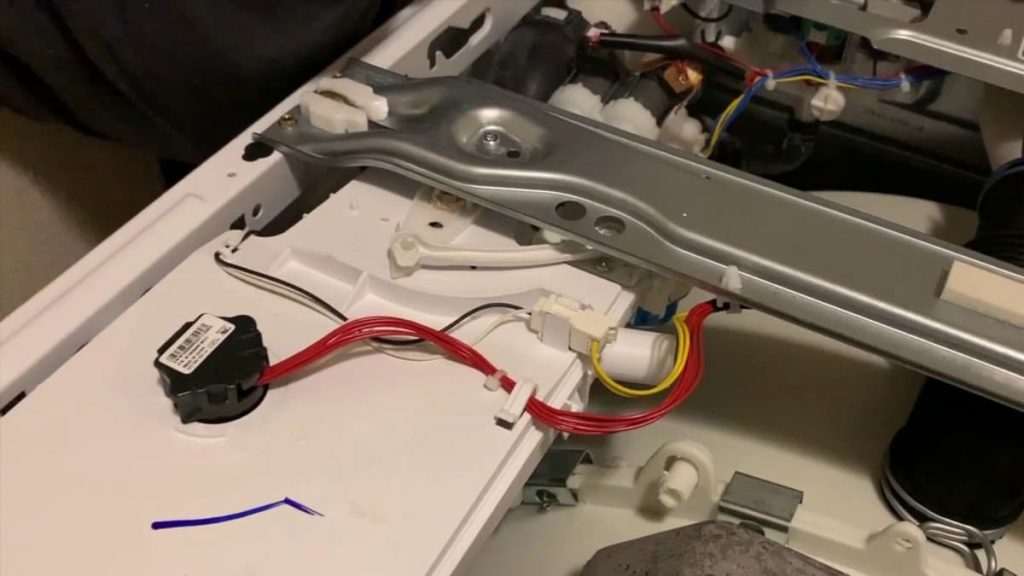

F8E0

Violation in the steam valve of the device. First check if it is connected at all, in particular, pay attention to the connecting hoses, then check the water connection.

F8E1

After the phase of pouring water, it did not appear in the drum. Check the hoses connecting the water supply and the washing machine: deformation in any of the sections can cause a problem. Also check the correct installation of the drain hose, the connection of the drum with the pressure switch tube, the pressure switch with hoses and pressure sensors.

F8E2

The metering motor cannot complete a complete movement phase. For troubleshooting, check motor and dispenser connections.

F8E3

Error code indicating that the washing machine is full. This could indeed be due to too much water and/or foam in the drum. Moreover, if the system cannot cope with an overabundance, then only then an error code appears.

The system cannot cope for such reasons as: a deformed drain hose, a leak in the exhaust valves, a blockage in the drain pump and an accident in the connection circuit of the drum – pressure switch tube – pressure hose – control sensor.

F8E4

The error code occurs when running a rapid test, as a result of which less than 100 ml of water entered the drum. For a solution, check the stability of the water supply, the position of the inlet hoses, and the connection of the water supply to the device.

F9E1

Error code indicating too long a phase of draining water after a streak. Usually, the solution to the problem does not require additional manipulations from the outside: the device will gradually drain the water, but a little longer than the time required initially.

After washing, it is worth checking the drain hose, the drain pump filter and the connection on the drum circuit – pressure switch tube – pressure hose – control sensor so that the problem does not recur.

F05

An error is displayed on the display if the temperature is out of range during the heating of the washing water.

Turn off the washing machine and check the temperature sensor: its serviceability and connection with other elements of the system.

F06

Malfunction of the drive motor tachometer, namely the inability to accurately set the speed of the engine. This problem often happens during high-intensity work, the machine turns off and then turns on again after a few minutes.

To prevent this problem, make sure that the transport system with all its components has been removed. Also check the correct wiring between the control units and the engine and inside their structure.

F07

A short circuit has occurred in the engine control unit, which is signaled by the main control unit and displays information on the display. After washing is completed, check the wiring between the elements of the washing machine, in particular between the central control unit and the motor and between the central control unit and the motor control unit. If no violations were found, examine the microcontrollers and the drive motor.

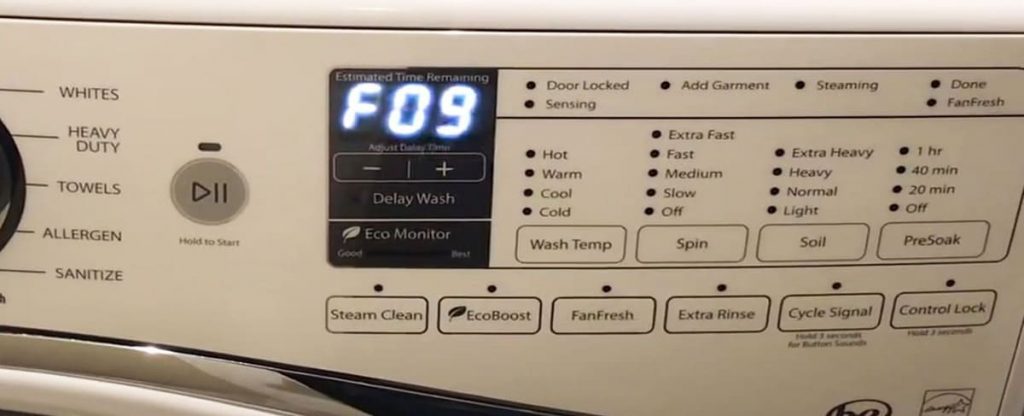

F09

In case the pressure contact is closed for more than 1 minute, the system is overloaded. The washing machine starts to work autonomously and does not respond to commands from the external display. You need to wait until the device completes all the cycles, and then only proceed with the repair and installation.

First disconnect the machine from the mains electricity and from the water supply. Next, one by one, start checking the drain hose and the drain pump for blockages and deformations, the wiring between the parts of the washing machine (pump, central control unit and pressure switch), the serviceability of the drain pump, inlet valves and pressure switch.

F10

If overheating of the central control unit occurs, the thermal protection on the radiator automatically turns on and the error code F10 is displayed on the display. To solve the problem, make sure that all wires are connected to each other correctly and that they are not deformed. Next, check and, if necessary, replace the motor and microcontrollers.

Also, a heat source in the room in the absence of ventilation can provoke a problem.

F11

An error has occurred between the system connecting the central control unit and the engine control unit. Moreover, the root of the problem may lie in a number of different reasons: damaged or loosely connected wiring between two elements, a faulty engine, a central control unit or a microcontroller.

Check that the harness on the central control unit is installed correctly as users often install it upside down.

F13

Error indicating that the metering motor is in the wrong position. The solution to the problem is to check the wiring between the dispenser motor and its top, as well as the dispenser device itself.

F14

Information is transmitted to the central control unit from other important components of the washing machine, for example, the engine control unit. Error F14 reports that an error was detected while scanning the incoming data. As a rule, error code F14 appears when there are power problems. The solution is to turn off the device for a couple of minutes, and then turn it back on. If this does not help, you need to check the health of the central control unit.

F15

Error code that occurs when the motor control panel detects a series of problems during operation. First of all, check the motor control panel inside: for cracks and breaks. Then make sure that the element is properly connected to the rest of the system and that all wires are intact. If you are sure that everything is working correctly and that there is no damage, check the drive belt, motor and microcontroller.

FDU

The washing machine door cannot be unlocked, which is why this error occurs. Moreover, the mechanism makes 6 attempts before highlighting the error code on the display. As a rule, FDU is associated with a malfunction of the lock mechanism or with the fact that a foreign object interferes with free opening. Additionally check the wire connections of the door to the central control unit.

FDL

The error is the opposite of the previous one: here the door cannot be locked. Moreover, as in the previous paragraph, the mechanism sends a notification only after 6 unsuccessful attempts to block the door. Usually FDL is associated with a malfunction of the lock mechanism or with the fact that a foreign object interferes with free closing. Additionally check the wire connections of the door to the central control unit.

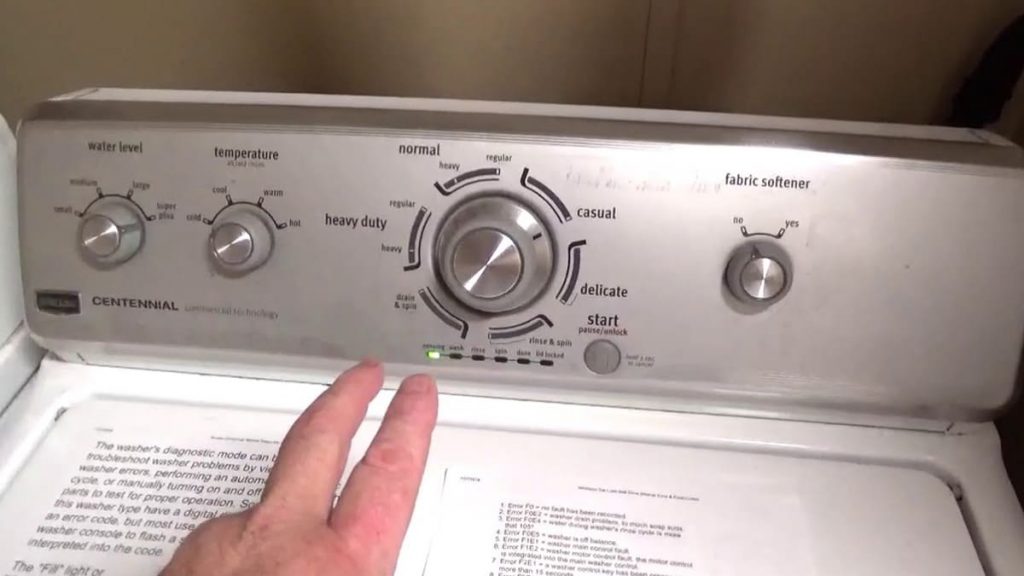

Sud SUDS LOCK

An error may indicate several failures at once: a broken pump, excessive load, an excess of foam or powder. If the error code is associated with the last two points, it can be eliminated by turning on the spin or rinse on the washing machine display. If this is not the problem, check for blockages in the hose, wiring between the drain pump, pressure switch and central control unit, as well as each of these elements separately.