Any housewife loses her temper when her dryer refuses to spin. After all, a woman will have to deal with a pile of wet things that will be difficult to quickly bring into the desired form. It is clear how unpleasant this situation is and how difficult it is to quickly find a solution to it.

In some cases, the malfunction can be quite significant and require immediate repair. But most often it can be eliminated right at home on their own at no extra cost.

With some effort in a short time, the machine will work exactly as it should. You just need to figure out what needs to be done first. Then a bunch of laundry will disappear very quickly and will not cause much trouble. But first, it is worth compiling a list of reasons why the unit stops spinning. These include:

- jamming of the drum bearing;

- violation of its sliding;

- engine malfunction;

- breakage of the tension roller;

- belt break;

- obsolescence of parts.

Drive belt break

This problem is often found in long-term household appliances. At first glance, it seems intractable. But with a certain amount of patience and purposefulness, it is possible to cope with it.

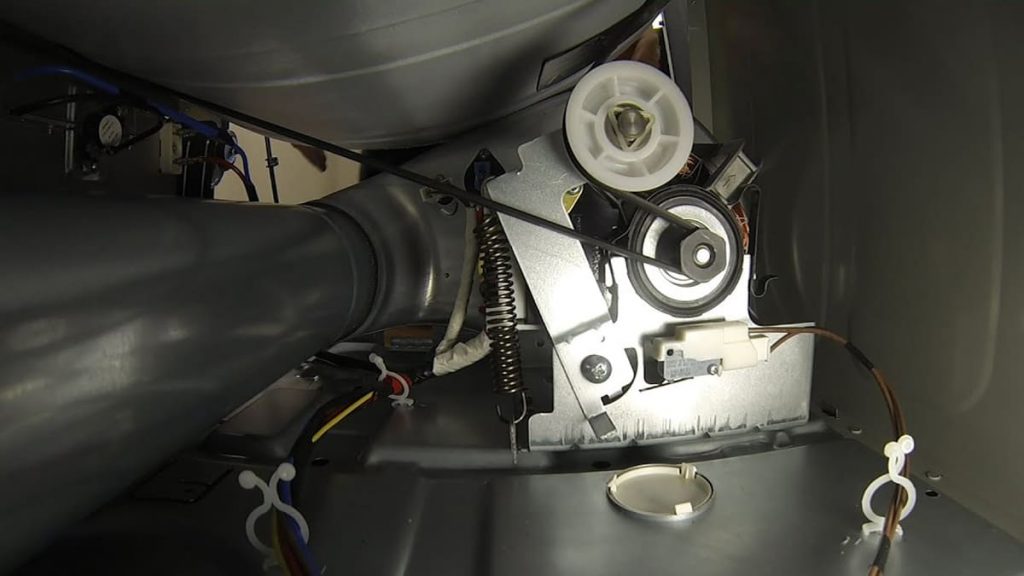

Almost any adult is able to independently eliminate such a malfunction. The drive belt turns the drum and gradually wears out over the years. In critical cases, it can even break. In order to change it, you need to stock up on a new one. You need to select it depending on the model number.

When the part is purchased, the front panel and baffle of the dryer should be separated to gain access to its internal parts. Then you need to carefully read the manual for it and replace the corresponding element.

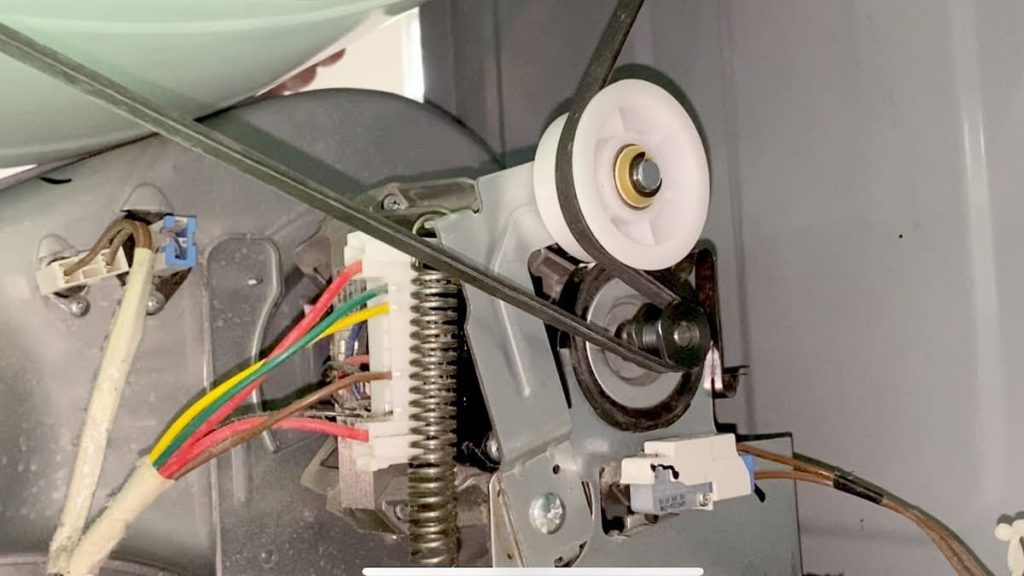

Idler pulley failure

The idler pulley or idler pulley helps to keep the drum belt taut to prevent it from slipping.

When this part is not sufficiently lubricated, it makes a loud creak. Most often it is accompanied by jamming and braking of movement.

When unpleasant sounds are heard, and then the car stops spinning, it is most often the pulley that is to blame. Then it needs to be replaced.

Worn drum axle or roller

Most of these units have 2 or more rollers supporting the back of the drum. Some of them are equipped with a couple of similar details.

If they wear out, the device stops spinning. It is best to establish the causes of the problem by listening to the creak during the operation of the equipment. If it is clearly audible, then it is just the axle or roller that emits it.

It is best in this case to replace them at the same time, then the dryer will last for many more years.

Drum slip injury

Some units of this type are equipped with plastic guides to support the front of the drum. If it is damaged or simply outdated, then it may jam. Then, during its operation, an unpleasant rattle will be heard.

If it is heard, then you need to take such a problem seriously. Such a malfunction increases the load on the drive motor, so it should be eliminated urgently.

It is quite simple to put a new element and immediately after changing it, the hostess can start processing a new batch of things.

Worn drum bearing

Some tumble dryers use a rear bearing to support the drum. If it wears out or is damaged, it will prevent the unit from spinning.

Usually in this case, a lot of noise is heard, so it is not difficult to detect this malfunction. Then you just need to replace the damaged part with a new one.

Drive motor problems

The drive motor of the device makes the drum rotate and at the same time acts on the fan impeller.

If his wheel is not clogged, then the drive motor is broken. Then it needs to be replaced or repaired. This situation is the most difficult of all listed, but it can be solved. It is enough to take the necessary tools, as well as show sufficient perseverance.

And in order not to be mistaken with the type of engine, you need to accurately determine its number.

Whirlpool appliances not spinning

The most common problem most Whirlpool dryer owners face is a broken drive belt.

Although the unit of this company is considered the most popular and reliable, it also wears out over the years. Any owner of household appliances faces a similar question. Therefore, if they stop spinning, then you should first find out if the drive belt is broken.

Maytag equipment not spinning

Maytag tumble dryers are also prone to all of these types of failures, but the drum roller wears out most frequently.

All parts of this type must be replaced at the same time to ensure the uniformity of their condition in the future. Otherwise, the owner of the unit will have to repair one or the other element all the time. And after the new ones are installed, Maytag appliances will still remain functional for many years.

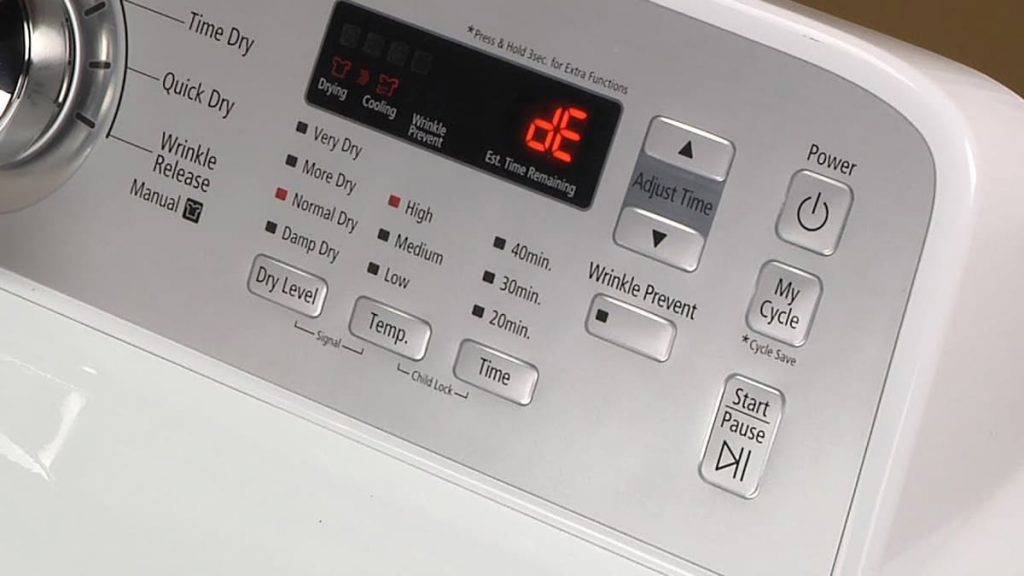

Samsung dryer fails

Samsung produces the most modern and digitally advanced units. But for all their modernization, they still retain many mechanical parts that are subject to wear.

Here are the things to remember:

- The condition of Samsung home appliances needs to be carefully monitored and repaired from time to time.

- In this case, attention should be focused on the drum bearings, because most often they fail.

- These parts are easy to purchase and replace, after which it is advisable to examine the condition of the drive belt as well.

- It is the second fastest wear. If any of its defects are noticeable, then soon it will break down and it will be necessary to put in a new one.