Sometimes, during a very large wash, the hostess suddenly finds that the dryer is not working. Then she is left with a large pile of wet laundry. If she does not have time to hang things on batteries and ropes for hours or take them out to the balcony, then the problem will have to be solved urgently.

If the Whirlpool unit refuses to function, there are usually several problems that are causing the problem.

Most often they are:

- failed switch;

- melted or burnt fuse;

- broken drive motor or belt;

- Difficulties with the supply of electricity.

Therefore, it is necessary to consider the main situations that lead to interruptions in the operation of a household appliance and find a way out of each of them.

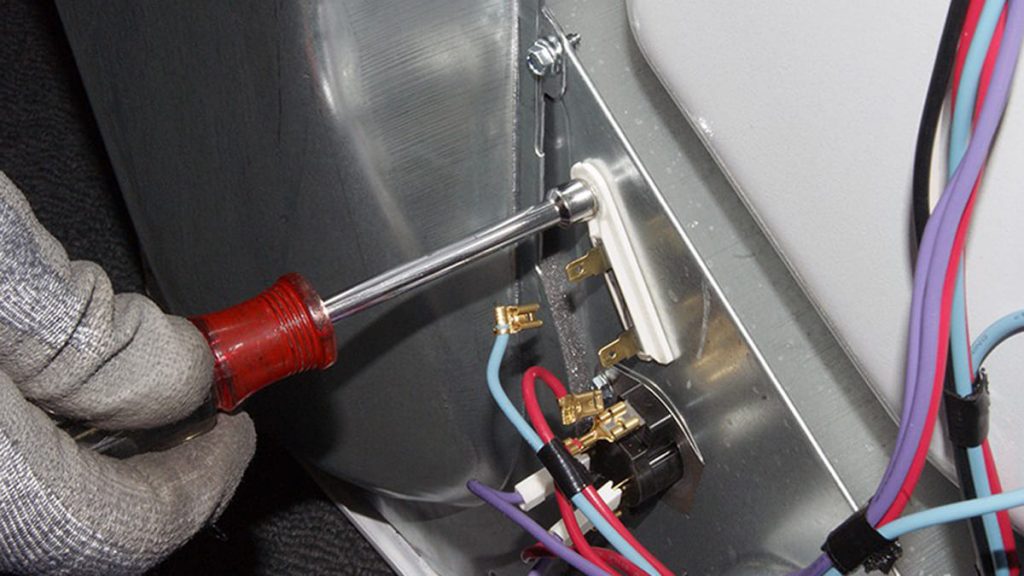

Thermal fuse blown

All modernized devices and other household appliances are equipped with thermal fuses to ensure complete safety of their operation. Their purpose is to protect Whirlpool parts from overheating.

The principle of operation of this part of the dryer is to automatically break the circuit when there is an overload. Its contact points, as a rule, are fixed by means of a special fusible material.

If an electrical circuit functions with an overload, then it heats up, its material melts, the contacts diverge, and the circuit itself breaks.

It must be understood that in this case the reason lies precisely in a blown and melted fuse. It should be precisely established that in this case it is he who prevents the dryer from starting. For such purposes, a multimeter will be indispensable. It will check for continuity. Therefore, this type of tool is always required to be kept somewhere nearby for machine repairs.

If the cause of the malfunction is a blown thermal fuse, then it should be replaced. These parts are not too expensive and it is very easy to buy them.

When installing them, it is also necessary to check the condition of the ventilation openings of the unit. If they are clogged with debris, you need to clean them out. Usually such a reason most often leads to the burning of the fuse.

Such information must be taken into account when a household appliance passes air through contaminated ventilation vents.

The fan has to function with great effort. The resulting energy overrun causes him to overheat his engine.

Before replacing a fuse or any other part of the device, it is necessary to de-energize it in order to avoid electrical injury.

The start switch, door, or belt malfunction

The dryer has a number of important switches that control a wide variety of options.

Therefore, it is worth carefully considering each of them and explaining in detail its main purpose.

The trigger element is an integral part of the machine, which activates the drive motor and is responsible for the process of thoroughly drying clothes. To check it, you must click on the special “Start” button, usually located on the main console. If the unit does not show signs of life, then the switch is most likely to blame.

The door version is a safety element and is used to stop the household appliance when the door is opened during the cycle of operation.

If the part is out of order, it is not able to determine if the door is closed. Then the appliance will not turn on.

To check the part, you need to close the door, activate the device and analyze the sounds of the triggered switch. If it functions normally, you will hear a click when starting the equipment. If everything is quiet, then the reason lies in the switch.

Don’t forget about the belt switch. Some Whirlpool models are equipped with it. It is designed to automatically stop when the part connecting the drum with the drive motor breaks. If it is out of order, then the dryer will not work.

But it also happens that with a faulty switch, it will not start even when the belt is intact.

It is not too important which type of unit relay is faulty. In any case, the procedure for its diagnosis and repair is very similar. At the slightest suspicion of a broken switch, it is necessary to conclude that the household appliance does not function for this reason.

Then you should take a multimeter and check the continuity of the switch. If during monitoring it is found that any such parts do not have it, then it is necessary to change them.

As in the past, the switch is not too expensive and is easily available in any store. Repair of spare parts is also not difficult, so it is easy to carry out even on your own.

Drive motor failure

This important part is directly responsible for providing power to all the mechanical parts of the device, which also includes the drum and fan. If the motor does not start, the cause is usually a blown fuse or one of the internal switches.

In some cases, the failure is associated with the engine itself. It may stop functioning when its bearings become blocked or worn out. Such parts are usually well lubricated, but the composition gradually applied to them dries out and loses its effectiveness.

If the motor starts to break down, it makes unusual sounds. At the beginning of the manifestation of a defect, the engine of the device emits a screech, buzz, ringing or grinding.

Before you start checking it, you need to check the degree of melting of the fuse, inspect the various switches of the equipment and its fan.

If the various switches and the thermal fuse are working properly, and nothing is obstructing the fan, then you need to make sure that the motor is working.

For this purpose, it is worth stocking up with a multimeter. If it shows that the motor is broken, then it needs to be replaced.

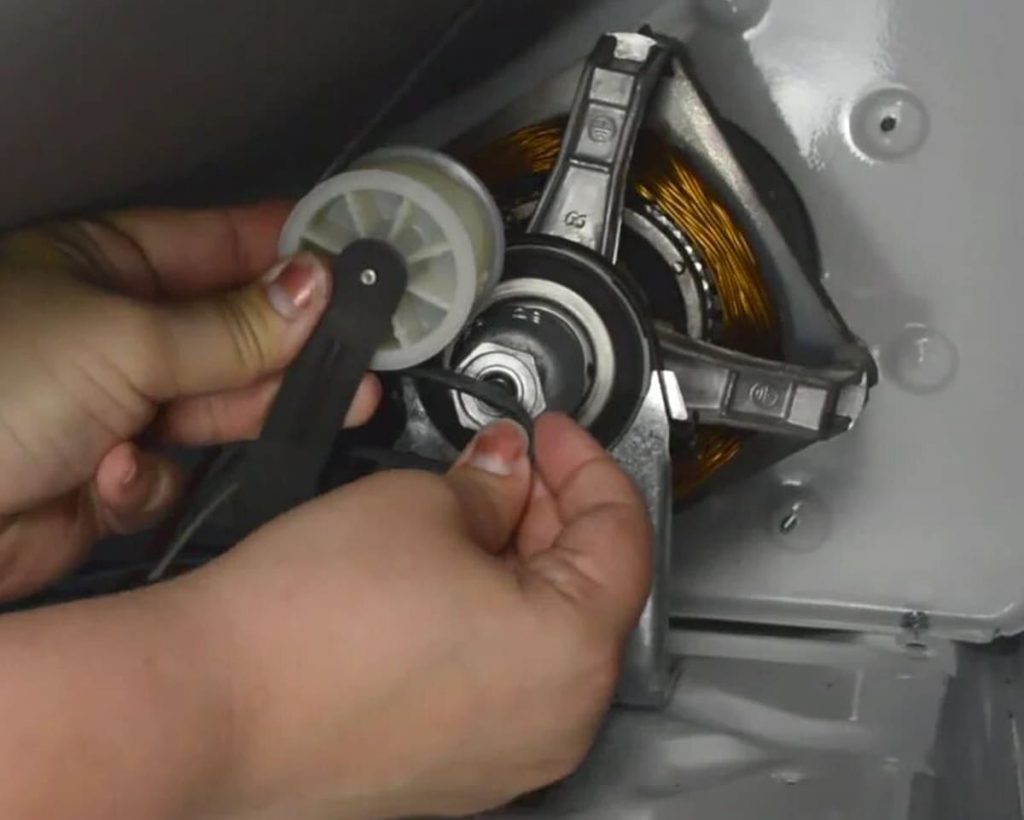

Drive belt break

It has already been mentioned here that the drive belt plays a very important role in the smooth operation of the dryer. But it is necessary to mention it again in more detail.

Such a part transfers the main power from the motor to the drum and fan.

The drive is usually made of special rubber, which gradually loses its performance. Then the belt begins to be exposed to excessive heat. Over time, it wears out and one day it breaks. Then the machine will not turn on even when the engine is running.

If its drive is out of order, it should be replaced. The part is not expensive, and it is very easy to install it.

Power supply failure

It often happens that the unit works quite well. But suddenly he suddenly refuses to turn on. Most often, such difficulties are associated with the complete absence of current. Somewhere there is a defect in the outlet for connecting a household appliance, a blown fuse or an open circuit.

- First you need to check the switch or fuse box.

- If tripped switches are noticeable on it, they must be reset.

- If blown fuses are visible, they should be replaced.

- If there is nothing special in the switch or fuse box, then you need to check the outlet more carefully.

- It is also worth stocking up on a multimeter or connecting another household appliance to it.

- Then you need to verify its functionality.

- If there is no feedback, replace the power point.

Control board failure

A similar part of the device is the main printed circuit board, which is most often located behind its control panel. It breaks very rarely. But when this happens, then the technique ceases to function.

Before you begin to examine the control board for troubleshooting various problems, you should first carefully monitor the performance of all other parts of the unit.

This rule is due to the fact that, most often, a breakdown is associated with them. Only when the owner is able to make sure that all parts of the household appliance are working properly, you can begin to study the control board.

If it fails, it needs to be completely replaced.

Checking the part is easy with a multimeter. A close inspection of the control board is also allowed in search of damage or scorch marks.

Timer failure

Usually devices of this type are equipped with a timer, which is used to control the passage of various cycles during the processing of linen. A similar detail is responsible for monitoring how long the equipment and its heater have been functioning. It also regulates the duration of cooling and performs many other functions.

Its breakdown is a fairly rare cause, but if it fails, the dryer will definitely stop. Therefore, this option should always be kept in mind.

A timer malfunction is necessarily included in the list of situations that must be considered in case of problems with the machine. In this case, it is necessary to start testing it, but it is recommended to conduct it only after checking all other parts of the unit.

If suspicion falls on the timer, then you need to use a multimeter to check the continuity. If the timer is broken, it should simply be replaced with a new part.