If the Shark vacuum cleaner suddenly does not light up the brush roller indicator, then most likely one of the most common problems in this case has arisen.

This signal usually does not appear due to:

- unit overheating;

- ingress of pollution;

- drive defect;

- errors when using a household appliance.

The roller in the Shark is located next to the suction head. It is designed to remove dirt, debris and dust from carpets and other places. The technology indicator lights up so that its owner understands whether the brush roller is functioning. It will glow green if everything is in order, and red if there are any problems.

Incorrect switch position

Shark usually comes with two built-in operating modes. One of them is responsible for full suction and is mainly intended for cleaning dust from a smooth surface (parquet or tile). The other is closely related to the functioning of the brush roller, most often designed for reliable processing of carpets with long pile.

The transition from one operating mode to another occurs using a special switch. It has “I” (suction) and “II” (brush roller action) marks. It is not always clear to the user which of them is responsible for what. Therefore, it is not always easy to immediately determine how the vacuum cleaner works.

In such a situation, the position of the switch must be checked. Its indicator will not light until it enters brush mode. Therefore, you need to immediately fix that it has a mark “II”.

If, after a thorough check of the unit, everything turns out to be in order, but the light does not appear, then the household appliance should be inspected for malfunctions.

Incorrect nozzle attachment

The nozzle of the device is usually located at the very end of the vacuum tube and is securely attached to the suction head. A similar detail is responsible for the thorough cleaning of a variety of debris and dust from the floors of the house. It consists of a brush roller and a motor that drives it.

The Shark head is attached to the body with a special hose. It is a conductor for its nutrition, and also throws dirt into a vacuum bag. Therefore, when the nozzle is incorrectly connected to the aspirator, its supply of electricity will not be sufficient. Therefore, the brush roller will not start spinning.

To solve this problem, you need to check that the head is securely attached to the hose. It is necessary to combine them and tightly fasten. Then the nozzle will snap into place and the brush roller will work as it should.

If the vacuum cleaner still does not work, then you need to inspect the suction and nozzle at the place of their docking.

You should also check the degree of their purity. A buildup of dirt can prevent the tip from being securely attached to the head. It is required to completely clean it and check the functionality of the unit again.

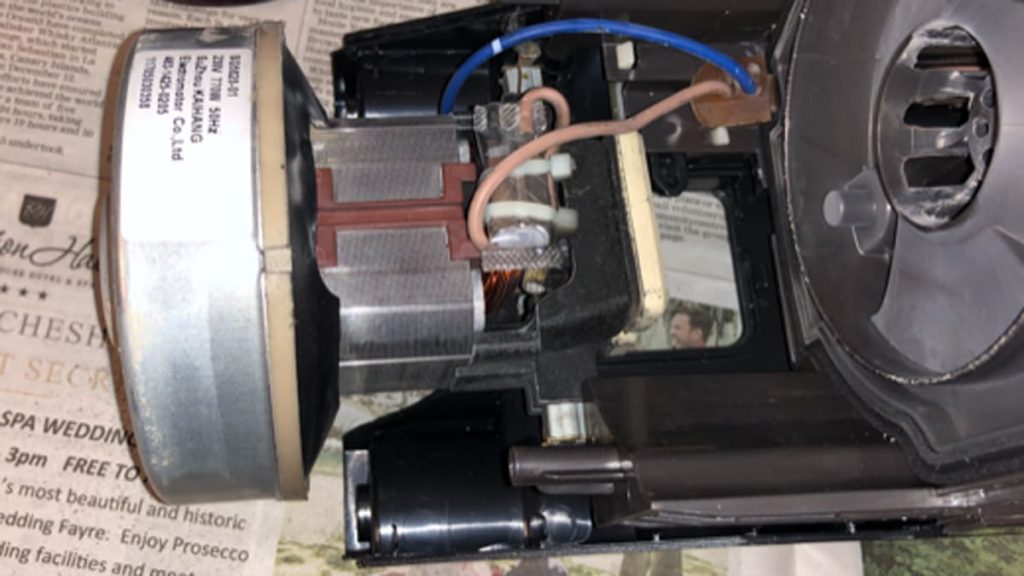

Overheating of the vacuum motor

A household appliance is usually equipped with two electric motors. The first ensures the constant operation of the suction fan, and the second is responsible for the operation of the brush roll through the action of the drive belt. In some cases, the failure of each of these parts can cause the indicator to turn off.

Both engines are capable of overheating due to completely different reasons.

If the main suction motor is out of order, then such a thing most often occurs due to the overflow of the vacuum bag. This is usually due to a clogged filter or blockage of the internal passage of the hose. Ensuring the passage of a full flow of air in the unit is necessary so that it cools the engine and helps it effortlessly suck up dirt and debris. If the jet ceases to pass normally or even partially, the engine will overheat.

If the obstruction reduces the intensity of suction created by the motor, then in order to ensure full cleaning, it will work with an overload, so after some time its temperature will reach unacceptable heights.

The brush roller motor can also fail, but for a different reason. It can overheat if the part is blocked and not spinning.

This also happens when the drive belt connected to the motor breaks. Without tension, the engine will spin too fast and soon also lack cooling.

In order to avoid overheating of the suction motor, you need to thoroughly clean the appliance.

- You should carefully inspect the garbage bag or dust collector of the device, the presence of which depends on the specific model.

- If they are full, then they need to be emptied or changed when filled to ¾.

- It is also worth removing the filters from the vacuum cleaner and cleaning or changing them well.

- It is advisable to examine the vacuum tube and the suction head in search of obstructions and remove from them everything that can disrupt their operation.

If the motor is already overheated, you will have to replace the brush roller drive belt or clean it.

The following will detail how to make such repairs. After troubleshooting, you will have to leave the unit for thirty minutes to completely cool it.

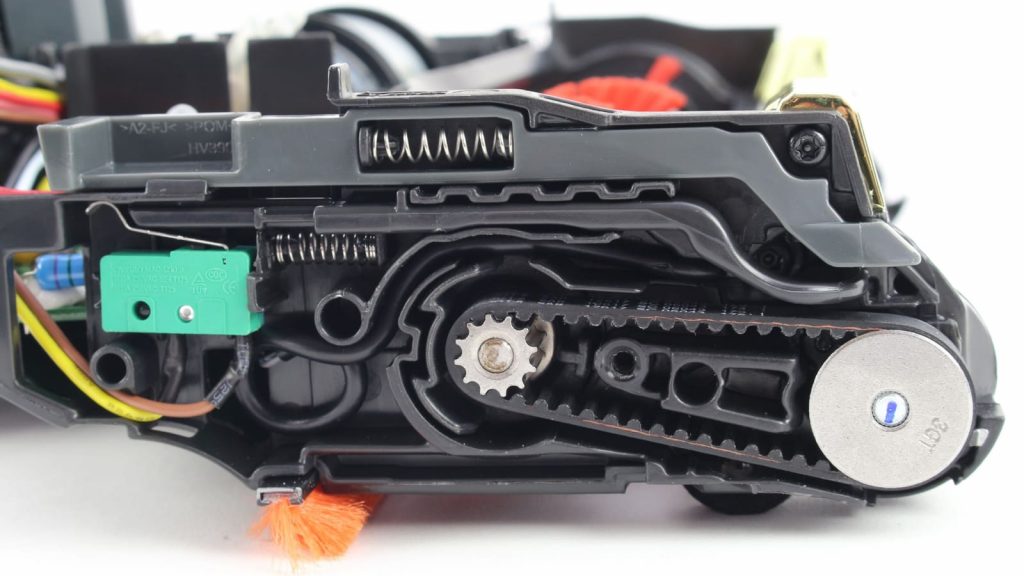

Breakage of the drive belt or its channel

As previously mentioned, the brush roller is driven continuously by an electric motor and a drive belt. Such a part is not too large and not at all complicated, but it performs the most important function in the operation of the brush roller.

The drive belt is made of rubber and therefore gradually wears out during long-term operation and becomes susceptible to various defects.

The tape is enclosed in a channel that is attached to the roller. This ensures that she does not jump out of her seat. If the passage is damaged, the part will simply not secure to the brush roll.

To solve this problem, you should change it or the brush roller. If the integrity of the channel is broken, then you need to purchase another part. It will not be possible to repair it due to the lack of necessary spare parts.

When repairing the drive belt or brush roller yourself, you need to disassemble the suction head of the device. Such actions are best done using a screwdriver. But in the event that the owner is not confident in his ability to disassemble and reassemble the equipment or is afraid of damaging the operation of his electrical parts, then it is better to contact a professional.

Brush Roll Jam

This rotating part is easy to find inside the suction nozzle of the vacuum cleaner. Its main task is to remove debris from carpets. The hard pile on the element roller picks up contaminants and pulls them out of the stuck places.

Brush rollers tend to tend to pick up hair. When they engage them from the floor, they become tangled around the working parts of the machine and prevent the brush roller from functioning.

When a large amount of hair penetrates into the internal cavity of a household appliance, the part is able to stop spinning. Then it is necessary to open the suction head of the device and find the mentioned part inside it.

When full access to the brush roller is obtained, it must be separated from the drive belt and removed from the suction head.

A ball of tangled hair is usually wound in a tight ball around the details of it. Therefore, it can be difficult to remove it. For these purposes, it is better to arm yourself with scissors and carefully separate them from the brush. When working with them, extreme care must be taken so as not to remove the bristles at the same time.

After completing the troubleshooting, install the part in its original place on the suction nozzle and reassemble the equipment. After that, you need to check the condition of the nozzle and check the full functioning of the Shark.

It is worth concluding that not every owner of a vacuum cleaner is able to immediately understand the intricacies of his work. Therefore, he does not always immediately realize why the brush indicator does not light on him.

It is very important to understand that in many cases such a problem can be fixed easily and quickly. Therefore, the tips given here will allow you to understand the features of the functioning of the unit and cope with the problems that have arisen in a timely manner.