The Shark vacuum cleaner is highly valued all over the world. It has exceptional suction power thanks to actively rotating brush rollers that pick up dust from the floor. If they stop spinning, then most likely they have hair or debris stuck in them. Often the switch that controls them also fails. Sometimes the problem is a faulty power supply. Failure of the internal relay, motor, circuit board, wiring and belt can also very often disrupt the operation.

Vacuum brush roller jam

Usually, the vacuum brush of the Shark unit stops spinning due to blockage or debris stuck in it. During the operation of the household appliance, it collects dirt on itself, and long hair and dust simply wrap around it.

In this case, it is necessary not to immediately take measures to clean the power head. Otherwise, the ball that has gathered on it will grow even more, and then the brush will stop spinning altogether.

To solve this problem, you need to remove the part from the device and place it on a suitable surface so that it is convenient to have a good look at it.

Cleaning must be carried out in accordance with the following rules.

- A large number of clogged areas can be freed by cutting the dust bundles. In this way, the overwhelming amount of hair and dirt is removed.

- When removing blockages, be extremely careful not to cut off the bristles or damage any part of the part.

- It is also required to open the sole of the nozzle and remove the brush, gaining access to all places of the greatest accumulation of dust.

Switch

Technicians Shark is equipped with a power relay directly controlling the brush. By actuating the necessary button, the owner effectively uses the brush.

Below it is a drive connected to the engine in the power head. It is designed to complete the circuit and supply power to the motor that drives the roller.

After using the Shark for too long, the belt wears out and stops functioning properly. In this case, after the power switch is turned on, no electricity is supplied to the motor. As a result, the main part of the vacuum brush does not rotate either.

To fix this problem, you need to remove the screws holding the outer cover in place and provide access to the inside of the vacuum cleaner. Then it will be easy to find the switch to be replaced.

Installing it is very easy. It is necessary to remove the previously installed part and strengthen a new one in its place. After that, you need to pay attention when connecting each of the wires in accordance with the diagram.

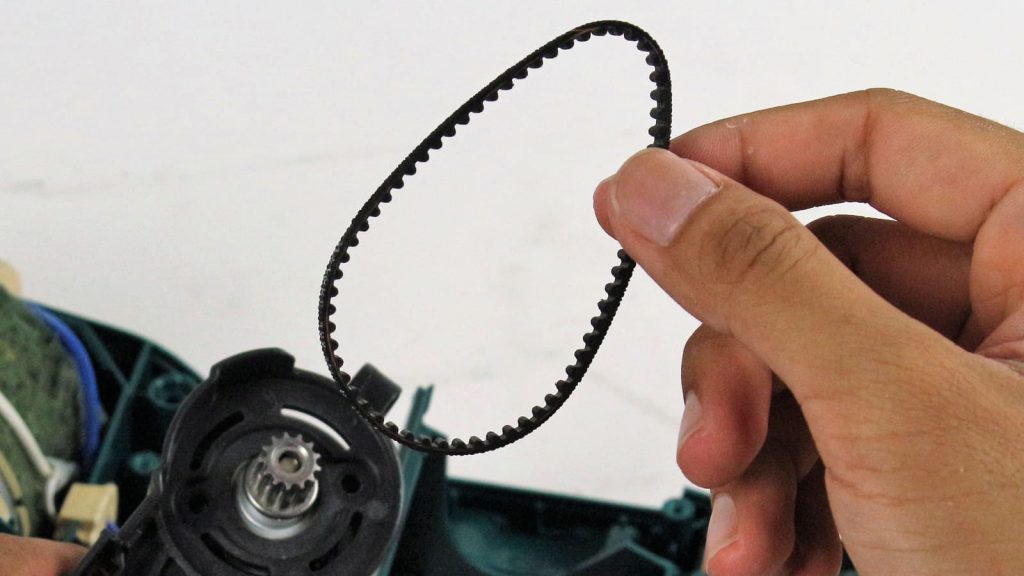

Brush Roller Belt Damage

The roller of this most important part is located inside the power head and is activated by the engine. Interacting with a rubber drive belt, it serves as a power transmitter to the brush. That is, the element twists it, and that, in turn, rotates the bar.

To stabilize the process, the drive belt must be in good condition. In addition, it should be very precisely aligned.

After a long period of operation, such a part wears out significantly. Usually, it cracks and breaks after a while. It also happens that it is no longer able to capture the moving parts to which it is attached. Then the brush roller stops rotating, despite the fact that the motor and other parts of the vacuum cleaner are in good working order.

A damaged belt is quite easy to change:

- it is necessary to remove the power head from the unit and put it on a flat surface;

- then you need to remove the screws and lift the top cover of the appliance to gain access to its interior;

- then you should get the brush roller and replace the faulty belt;

- you also need to make sure that it is correctly installed in relation to the main parts and securely wraps around them both;

- at the end of the work it is necessary to replace the cover.

Difficulties with internal switch and powerhead wiring

In the previous part, it was detailed how the electrical power switch normally operates to drive the brush roller motor. But in the power supply there is also a second similar relay, designed to rotate the part when the handle of the device is tilted back.

That is, such a switch stops the motor when the Shark equipment is standing upright. Several wires are also connected to it, enclosed in a power head.

As mentioned earlier, the long-term operation of any parts of the vacuum cleaner gradually wears them out. If the brush roller stops spinning when the unit is tilted back, then most likely the switch has failed in this case.

In addition, its wiring is easily damaged or twisted within the small space containing it. As a result, it becomes difficult to provide the motor with power. Then the same problem is formed, which is that when turned on, the motor does not receive current. As a result, the vacuum brush does not spin either.

When working with this breakdown, you need to disconnect the power head, remove its covers and open a free view of the internal surface of the device. There you can find any damaged wiring and bring it into proper form.

If a damaged motor is found, replace it immediately. It is required to remove the existing switch and put a new one in its place. It is worth being extremely careful when working with the power head cover, since keeping its wires twisted will lead to the fact that the malfunction will not go anywhere and will continue to disrupt the operation of the equipment.

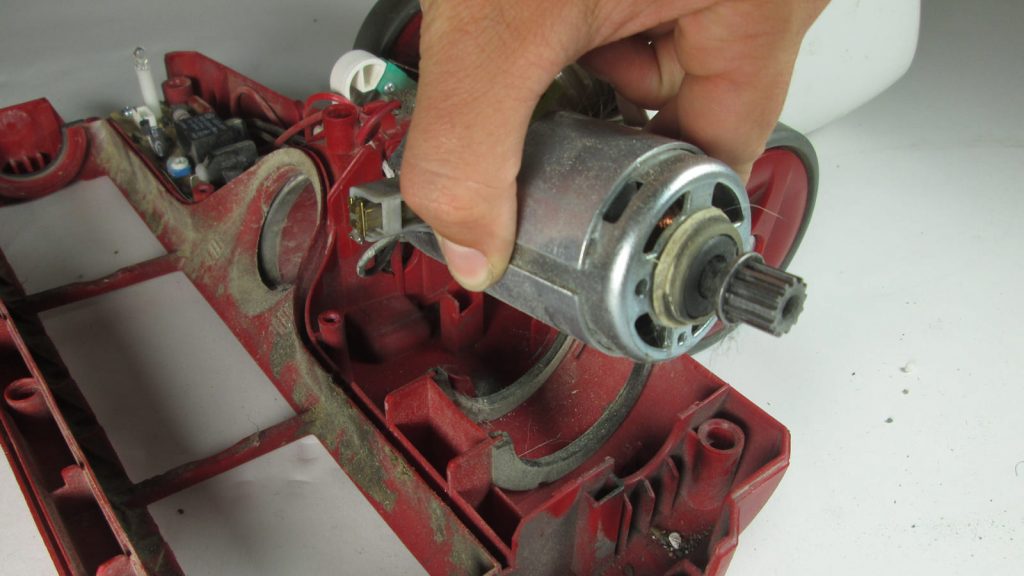

Motor brush shaft problems

Such a part is driven by a small motor located in the interior of the power head. The motor interacts with a rubber belt that transmits electrical energy to the brush roller.

The element is powered by a pair of switches. One of them is located inside the powerhead and powers the motor every time the Shark leans back.

The other is located on the vacuum regulator and allows the owner of the vacuum cleaner to turn it on and off when he needs it.

The motor may burn out or be damaged. A similar thing will happen the more likely the longer the life of the unit. If the brush roller is constantly clogged with dirt, the motor is under heavy load. An excess of energy is needed in order to keep the brush roller constantly rotating. Naturally, the part quickly burns out.

If a household appliance is used for a long period, the engine also wears out significantly. This also causes it to break.

Changing parts is not difficult. As in the previous cases, you should remove the power supply and lift the top cover or panel of the device. After that, you need to disconnect the motor from the electrical connectors and take it out. After installing a new one, you need to reconnect it to electricity.

At the end, the belt is wrapped around the motor and brush, and then carefully aligned.

At the end of the work, you need to replace the cover.

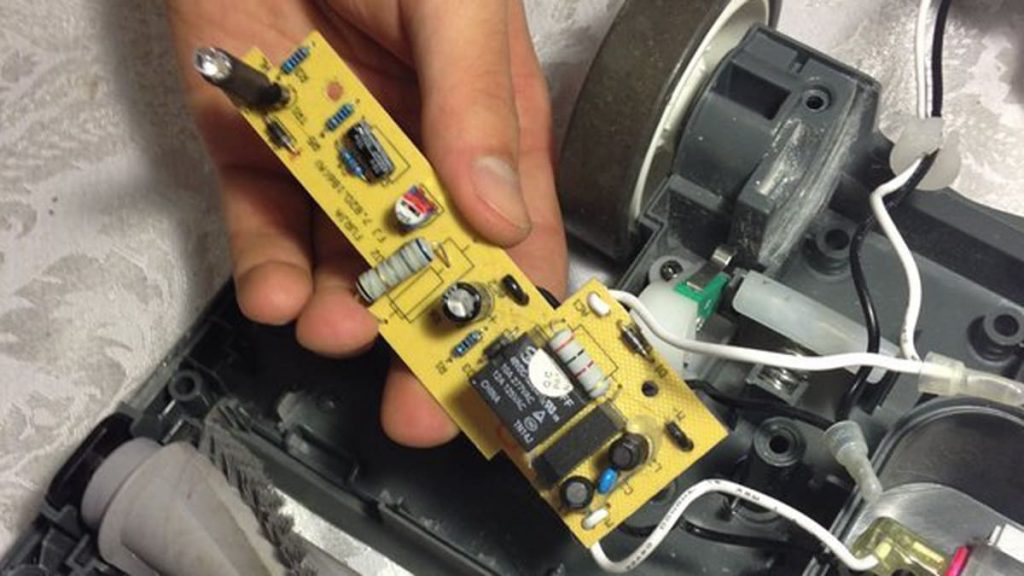

Brush circuit board problems

There is a brush roller circuit board inside the power head. It contains a number of small electrical elements that control the power supply to the motor.

Such boards often fail due to short circuits, excess moisture or excessive heat, and also due to general wear and tear. When any part is damaged, it stops the supply of electrical current to the motor. Therefore, the bar of the vacuum brush stops spinning as it should.

To fix it, you need to follow a series of steps similar to those mentioned earlier.

You must unscrew the top cover of the unit and provide yourself with access to the interior of the power head. Then it will be easy to replace a small printed circuit board, located in the appropriate place and connected to several wires. It needs to be removed and a new one installed in its place.

At the end, you should check the position of the cords so as not to confuse anything.

At the end of the process, it is required to strengthen the cover of the power head and connect it to the Shark household appliance.

Incorrect vacuum setting

As many owners of such a device know, it is equipped with 2 built-in cleaning modes.

The first one is aimed at cleaning wood and tiles. Then only the suction parts work, not the brush roller.

The second performs the task of processing carpets. In this mode, the entire scope of work is applied.

The Shark technique does not automatically switch to the required mode when cleaning the surface. The owner needs to configure this setting. That’s what the vacuum switch is for.

Sometimes it is difficult for the owner of the vacuum cleaner to determine which cleaning mode it is in. Then he sometimes finds it difficult and thinks that the brush roller refuses to function. And you just need to switch the unit to a certain option.

The Shark household appliance is equipped with a light indicator that indicates the status of the brush roller. If green is on, it is functioning normally. If red is visible or the sensor does not respond, then the part is not working.

It also happens that the owner of the device has switched between modes several times, and the brush roller still does not rotate. Such a thing clearly indicates its malfunction.

Incorrect attachment of the suction head

This part is part of the Shark technique that comes into contact with the floor and sucks up a wide variety of dirt. In a vacuum, it incorporates a motor for the brush roller, which needs an uninterrupted electrical supply.

The suction head is provided by it through a vacuum tube that does not maintain a passage between it and the Shark body. In addition, the part provides power through the built-in wires.

If it is not properly attached to the vacuum tube, it will not receive electrical energy. Then the owner of the vacuum cleaner will have to check the accuracy of attaching the suction head to the hose.

He also needs to check the accuracy of their alignment with respect to each other. If any violations are found, they should be eliminated. The part must be very correctly fixed on the tube.

It is also required to monitor their points of contact so that the connection is not interrupted by anything. If they are dirty, they should be cleaned immediately and thoroughly. Then it remains to mount the suction head to the hose again.