Most housewives try to save on their daily expenses. Therefore, one of the best options for effective financial savings is the repair of equipment made on your own. It becomes especially important in relation to large units that are difficult to replace.

In every home, the most important household appliance is a washing machine. Therefore, any owner will be alarmed if he hears a loud knock during her work.

Front loading units: cracked drum

Nowadays, this type of household appliance is very popular, so it is found in almost any home.

Its mechanism is designed so that the stainless steel drum is not vertical, but horizontal. This design contributes to its free rotation, and the specified part is fixed with a basket or spider.

Washing machines from different manufacturers have removable elements, but for some units, they are permanently built into the drum. Therefore, their breakdown is often associated with the fact that such an element is made of aluminum or an alloy. This material is subject to corrosion.

Therefore, with a serious defect, the household appliance fails and then a loud knock will be heard during rotation. The main way to check its condition is to rock the drum with your hands from the bottom up. If it moves too fast, then the spider arm may be broken.

When replacing it, it is necessary to unplug the washing machine from the mains and provide access to its rear. Then you need to open the corresponding panel and get to the drum. You should make sure that the spider is removed and check its functionality.

To install a new part from the manufacturer, you must first remove the fasteners, and then install it. At the end, the panel is put into place. It is worth immediately connecting the machine and making sure that it is working properly.

Worn shock absorbers

All household appliances need to be handled with the utmost care to maintain optimum performance. Because they are exceptionally expensive, many owners are unable to purchase new appliances quickly. So they should know how to fix it.

Most often, a strong knock of the drum during the spin cycle is heard when the shock absorber fails. It is used to provide balance when spinning.

If it is missing, then the problem is further exacerbated during the spin cycle. This difficulty is due to the fact that then the drum spins very quickly. If the malfunction is not eliminated in time, then it will beat against the inner surface of the washing machine with a loud thud.

To check the system, access to the inside of the unit is required. It is necessary to remove its back panel and find out why such a sound is heard. If defects are found, shock absorbers must be purchased from the manufacturer. To replace them, unscrew the old part from the frame and drum, and then remove it.

After that, you need to put the back of the household appliance in place and turn it on. During the spin cycle, loud sounds should no longer be heard.

Suspension rod wear in top-loading washing machines

Units of this type are most often found in the economy. Most of them are very expensive and replacing them with every breakdown is not a way out.

If a loud knock is heard during spinning, then damage to the suspension rod is not ruled out. This problem also leads to imbalance. Its presence is very important for household appliances with vertical loading. When the drum is spinning at high speed, it can damage the inner surface of the equipment. Therefore, it is important to ensure its strong position.

This type of washing machine is equipped with 4 suspension rods attached to the frame. They ensure that balance is maintained in her work. Therefore, if a knock is heard during the spin cycle, then it indicates that the corresponding suspension element has failed.

After studying the manual for the machine, the algorithm of actions is as follows:

- checking the disconnection of the unit from the network;

- detaching it from the wall;

- gaining access to its interior;

- search for suspension springs;

- inspection of 4 rods;

- replacement of worn or damaged parts;

- installation of a cover into place;

- connection of a household appliance;

- checking its work.

Rear bearing wear on front loaders

The main bearing in all models with any type of load is associated with the free rotation of the drum. In front-mounted washing machines, it is located at the back of the drum and is protected from direct contact with water by a special seal.

If a loud thud is heard during spinning, then usually the cause lies in significant damage to the bearing of front-loading machines. Such a breakdown can cause serious damage to the drum fasteners. If there is a clear suspicion that this is the case, then you should purchase the required part from the manufacturer. It is also worth checking with him whether self-repair is possible in this case.

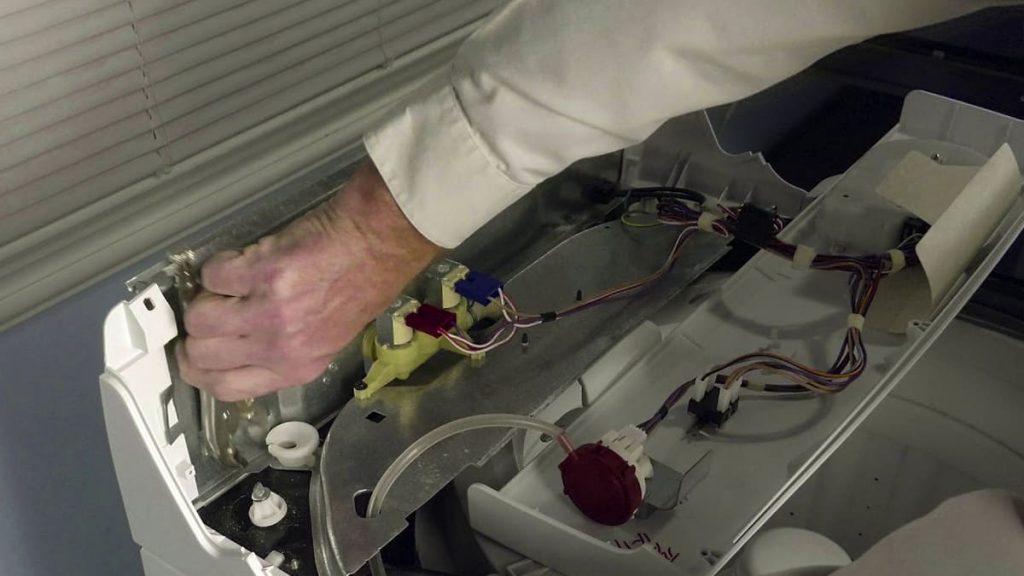

After purchasing a new bearing, it is necessary to provide full access to the internal space of the unit. As always, you first need to check its disconnection from the network. The access panel should then be removed to inspect the drum.

It is required to remove the installed bearing and carefully inspect it for serious defects. If they are found, it is necessary to replace the part with a new one. In the end, the household appliance is assembled in accordance with the diagram, its power cord is connected and the functionality is checked.

Main drum bearing wear on top loading devices

Such a part in models with vertical loading is intended for normal rotation. When spinning, it is very important that nothing interferes with it and does not create a threat of jamming or interference.

The main tank bearing is a sealed element with small steel spheres under a lubricated protective housing. It is designed to reduce friction inside the washing machine.

If a loud noise is heard inside the top-loading unit, then most often it is the main tank bearing that is damaged. And if the drum is unbalanced, then it can damage it, and then a strong knock will be heard.

The change of the specified part is as follows.

- The required item for the top-loading appliance is purchased from the manufacturer only.

- First, make sure that you have a stock of all the necessary tools for removing and mounting the bearing.

- Equipment is disconnected from electricity.

- It must be placed in such a way that it is convenient to work with it.

- The part shown is under the agitator tower. If it is not in this type of washing machine, then you should look right under the central cover.

- After removing the old bearing, a new one is mounted in its place.

- Then the unit is fully assembled again according to the diagram in the user manual and connected to the power supply.

- At the end of the work, a series of test runs is made to check the absence of any extraneous sounds.